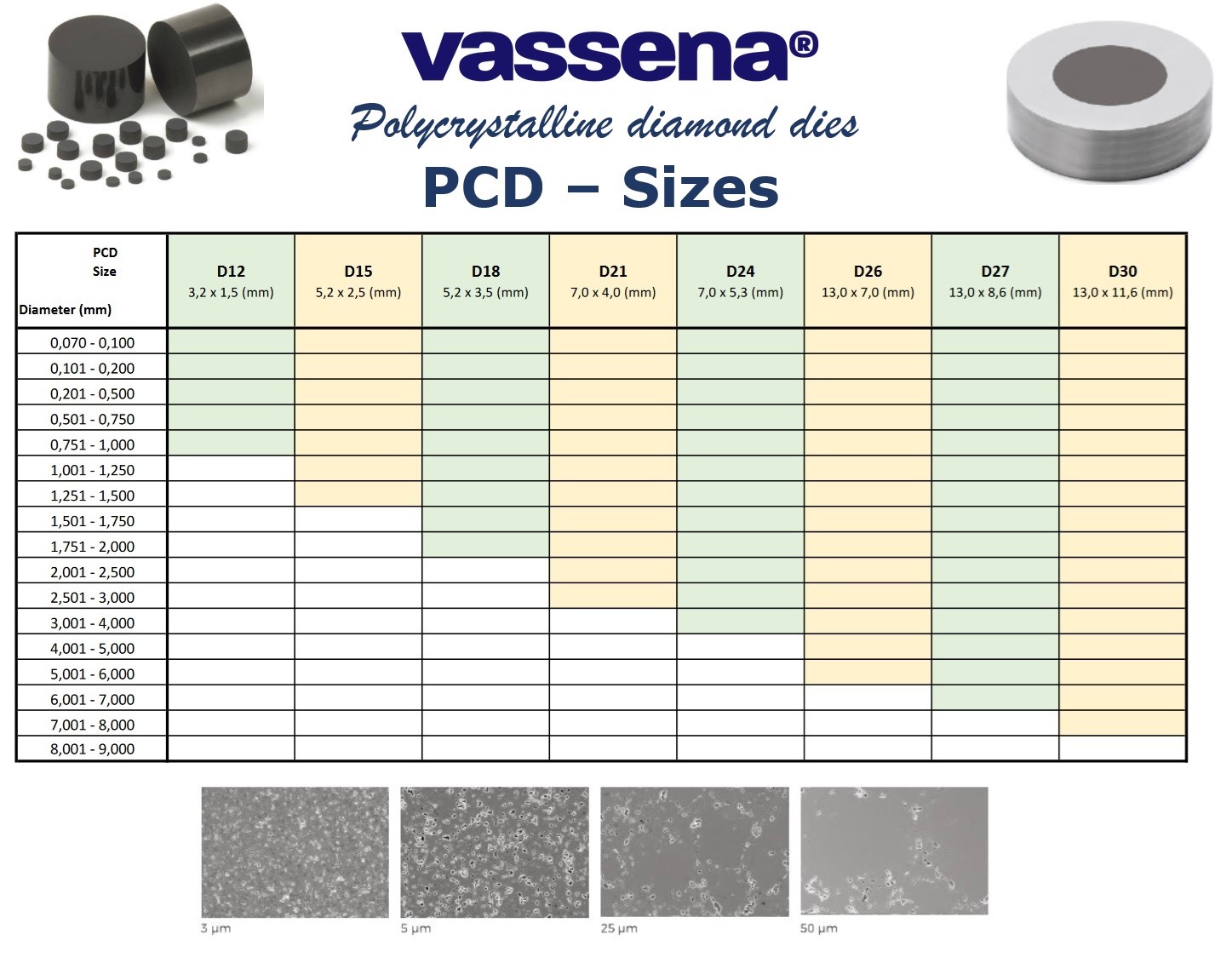

FILIERE PCD E NATURAL DIAMOND

|

|

SCARICA IL MANUALE |

|

|

|

SCARICA IL MANUALE |

|

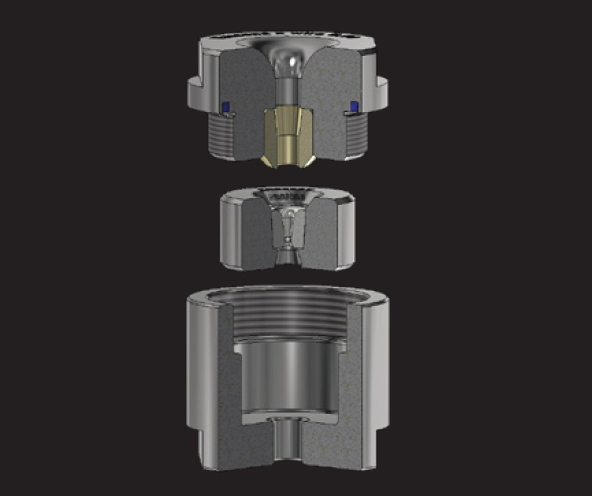

After many researches, feasibility studies and tests, Vassena developed a new type of die that coupled to a pressure die can give a performance 3-4 higher times to the one employed now in the present pressure system.

The die type “19.38” is a special die, that is produced in small quantities, to be used only on final and small diameters on dry drawing machines with pressure die. Type of material, geometries and other elements ensure a longer die life.

Avec l'image suivante, Vassena Filière anticipe l'annonce d'une innovation importante, qui concerne un nouveau modèle de filière de tréfilage.

Le nouveau modèle appelé 19.38 a des caractéristiques très particulières et sera officiellement présenté sur ce portail en Janvier 2013.

Vassena est synonyme de qualité dans la production de filières et d'équipements de tréfilage. La société produit des filières de tréfilage ronde, filières de forme, douilles de pression, filières profilées, patins en carbure de tungsten integral, polisseuses de fil, et matériaux auxiliares pour la rectification des filieres.

After many researches, feasibility studies and tests, Vassena developed a new type of die that coupled to a pressure die can give a performance 3-4 higher times to the one employed now in the present pressure system.

The die type “19.38” is a special die, that is produced in small quantities, to be used only on final and small diameters on dry drawing machines with pressure die. Type of material, geometries and other elements ensure a longer die life.

After many researches, feasibility studies and tests, Vassena developed a new type of die that coupled to a pressure die can give a performance 3-4 higher times to the one employed now in the present pressure system.

The die type “19.38” is a special die, that is produced in small quantities, to be used only on final and small diameters on dry drawing machines with pressure die. Type of material, geometries and other elements ensure a longer die life.

Nasce una nuova generazione di filiere: Vassena 19.38

Dopo molte ricerche, test e studi di fattibilità, Vassena ha sviluppato un nuovo tipo di filiera per trafilatura che in accoppiata alla bussola di pressione può dare un rendimento 3-4 volte superiore a quello registrato col sistema di pressione usato finora.

La filiera di tipo "19.38" è una filiera speciale, che viene prodotta in piccole quantità, da utilizzare solo su diametri piccoli con macchine trafilatrici a secco, con filiera di pressione. Tipo di materiale utilizzato, geometrie e altri elementi garantiscono alla filiera una maggiore resistenza, e una vita più lunga.

Vassena Filiere presenta: filiera VG402R per trafilatura ad alta velocità di filo

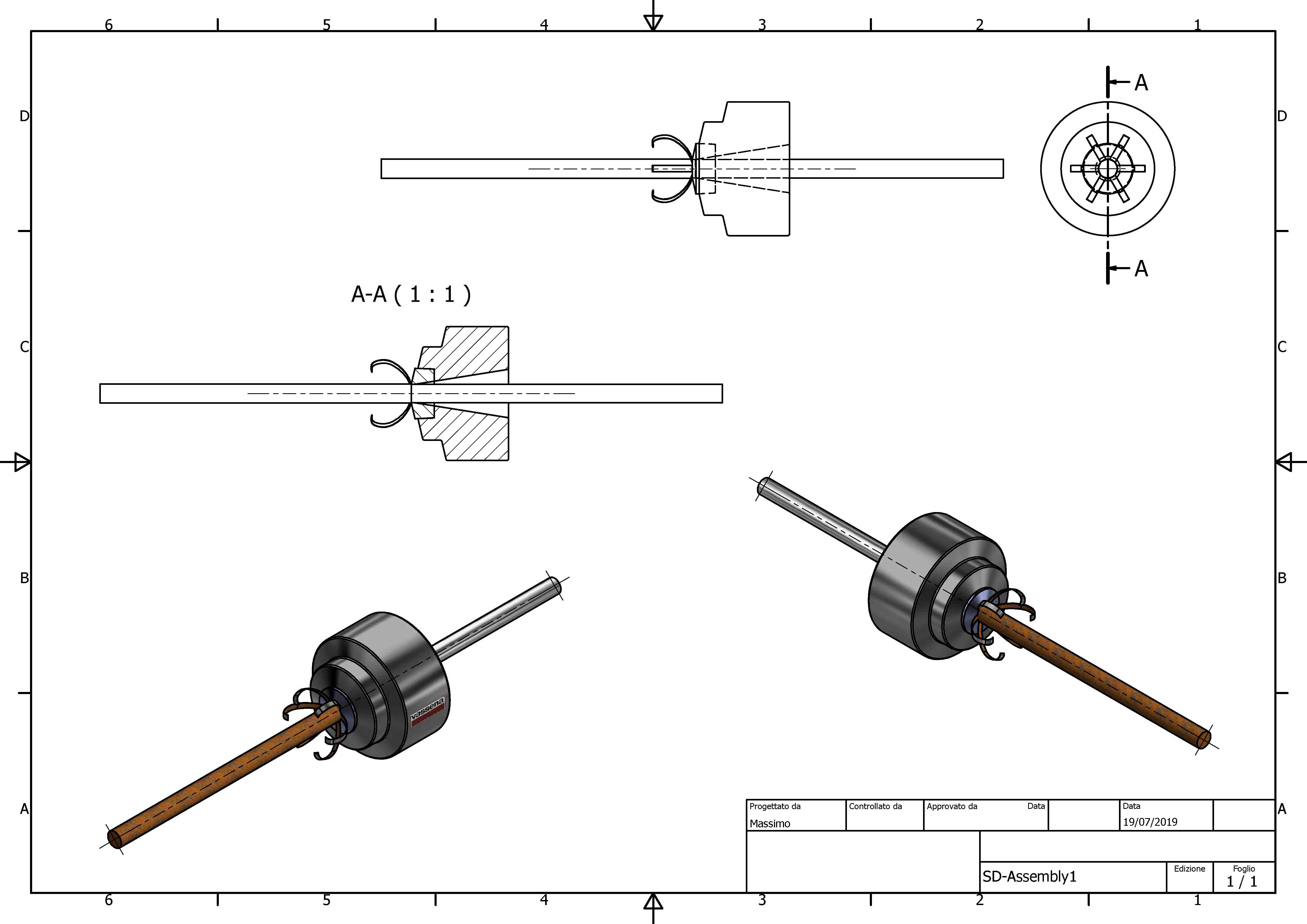

Vassena Filiere Srl presenta in anteprima al settore della trafileria le nuove Filiere VG402R, progettate per la trafilatura ad alta velocità del filo. Queste sono dotate di un'innovativa bussola di pressione, sviluppata seguendo un nuovo criterio di calcolo delle geometrie interne, sia della filiera che della bussola, al fine di ottenere un maggior ancoraggio del lubrificante sul filo, riducendo così l'attrito che si genera durante la trafilatura. Automaticamente viene incrementata la velocità di trafilatura e la durata della filiera e ridotta notevolmente l'incidenza del costo della filiera sul processo di lavorazione.

|

|

|

|

|

|

3 key points of Vassena's new nano-diamond coated dies

Vassena Filiere has recently introduced a new technology to its range: nano-diamond coated dies (NDCD) also for bars and tubes up to a maximum diameter of 60 mm. These dies offer wire manufacturers significant advantages over traditional tungsten carbide dies. Let's explore their key strengths.

Nano-diamond coated dies: features and benefits

The nano-diamond coating is applied through Chemical Vapor Deposition (CVD), which gives the die exceptional hardness, wear resistance, and surface finish. This results in greater durability, improved wire quality, higher drawing speeds, and heat resistance. These features make it ideal for drawing both carbon and non-ferrous metal wires.

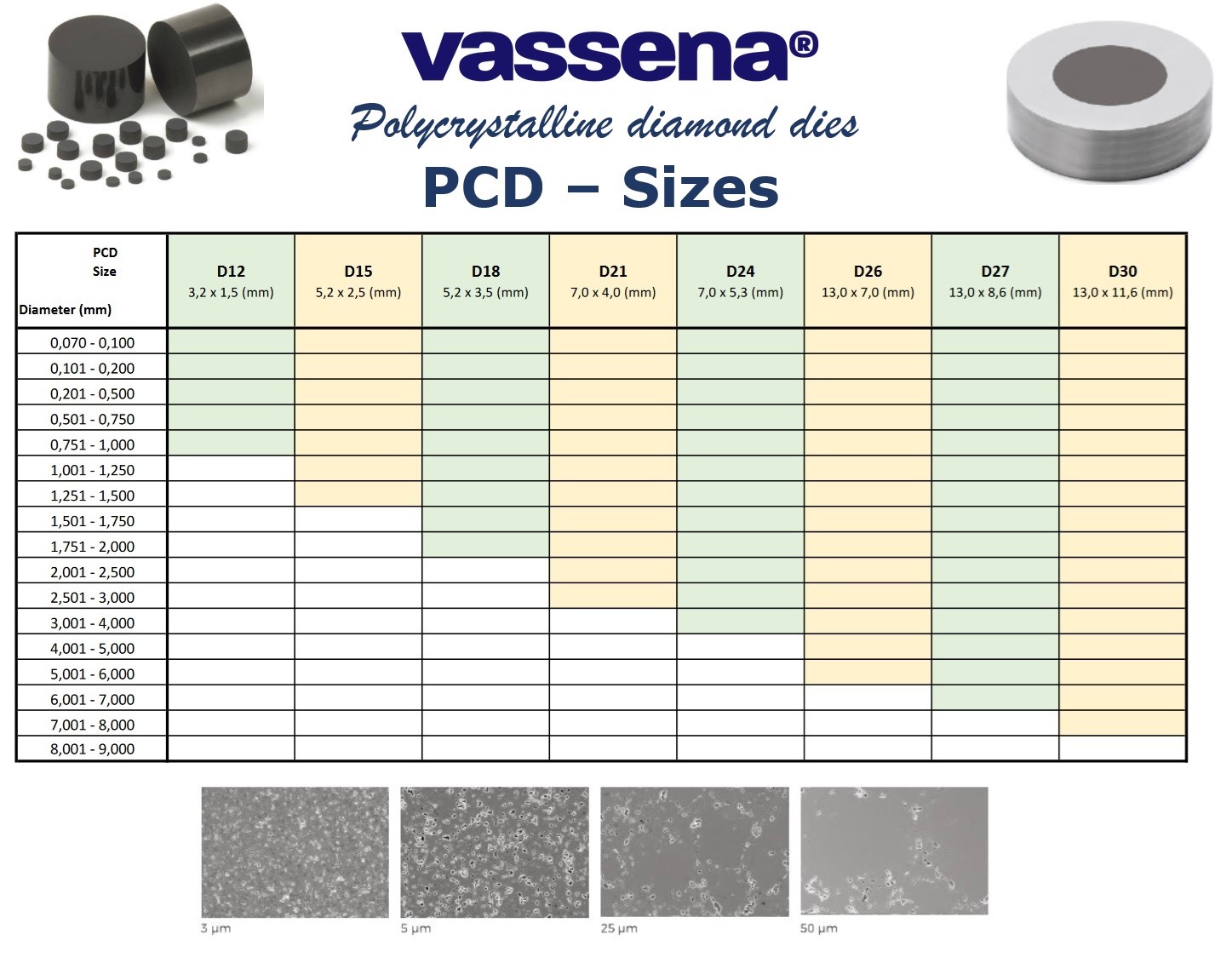

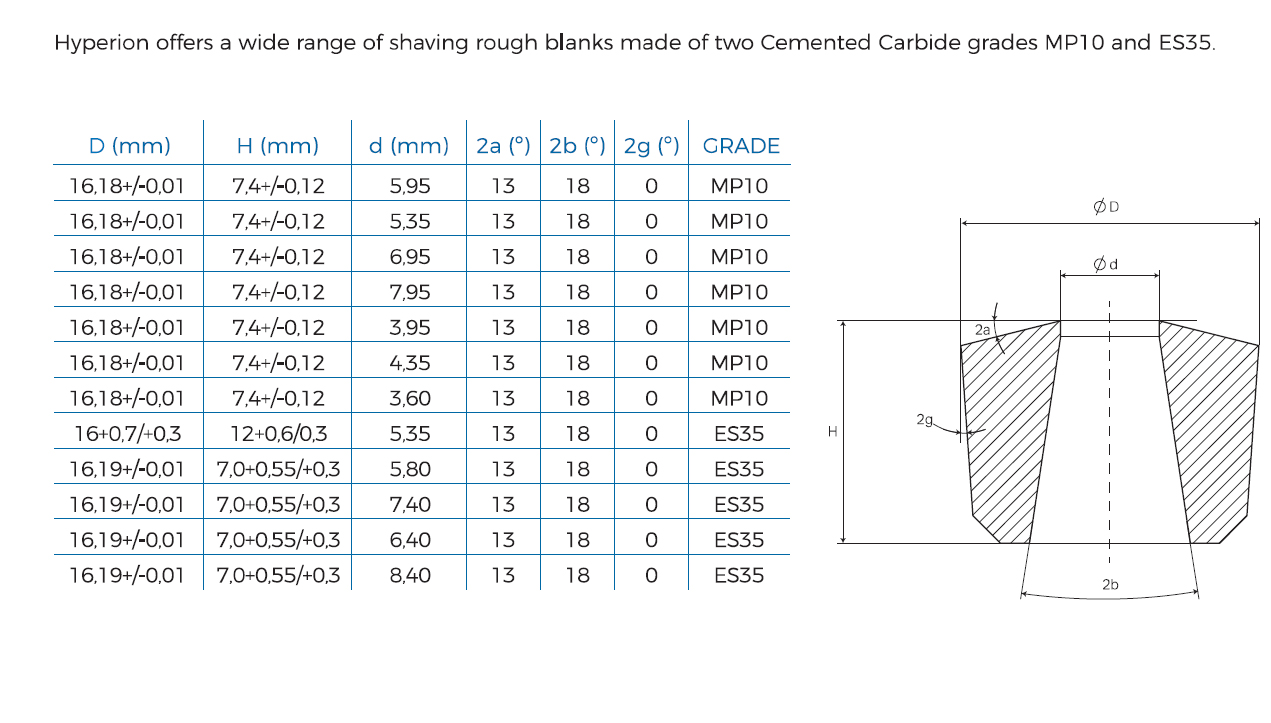

The new Vassena NDCD series is available in diameters from 0.40 to 60 mm for wires, bars, and tubes. The company uses top-quality materials, including those from Hyperion, a long-term partner of over 30 years. Production has been moved to a dedicated facility where every process is closely monitored and controlled. Moreover, Vassena's NDCD dies can be customized according to the client's technical specifications.

Enhanced hardness

The diamond coating allows these dies to reach a hardness level of 10,000 Vickers. In comparison, tungsten carbide dies, commonly used in the industry, are significantly softer and less resistant. The diamond series dies are thus ideal for drawing medium carbon wire and non-ferrous materials such as copper, brass, aluminum, and titanium.

Extended durability

The increased hardness of Vassena's dies also makes them incredibly durable. It is estimated that NDCD dies can last up to 30 times longer than tungsten carbide dies. This represents a substantial improvement, traditionally only seen with non-ferrous and low-carbon content materials.

Reduced friction

An additional benefit of nano-diamond coated dies is the significant reduction in the coefficient of friction during extrusion. This results in less die wear, lower lubricant consumption, and reduced energy requirements for the entire process.

The nano-diamond coating not only enhances the overall efficiency of the wire drawing process but also reduces operational costs. For this reason, Vassena has integrated this technology across its entire product range, including the flagship VG402R dies with pressure bushes.

SCARICA IL DATASHEET |