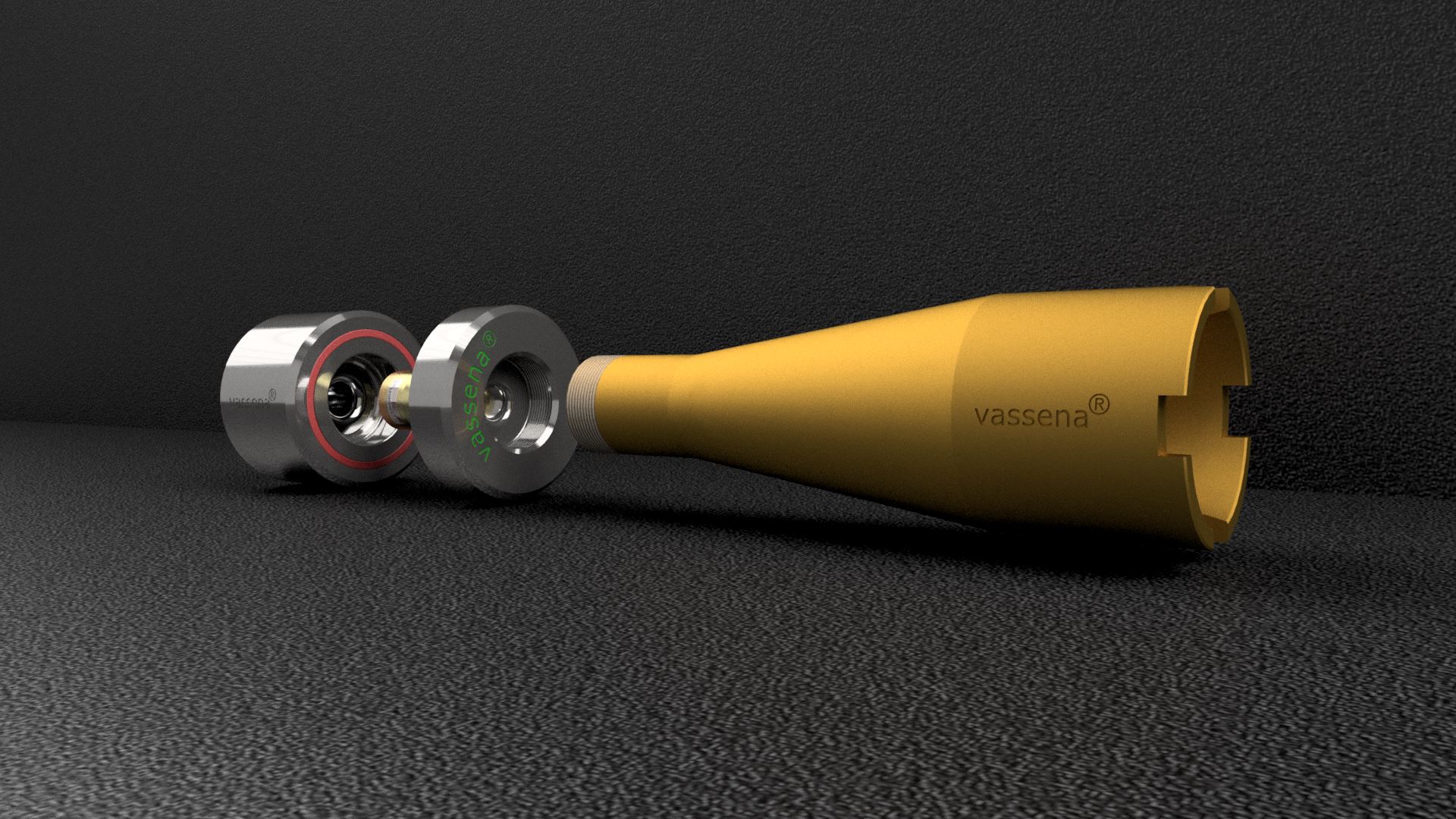

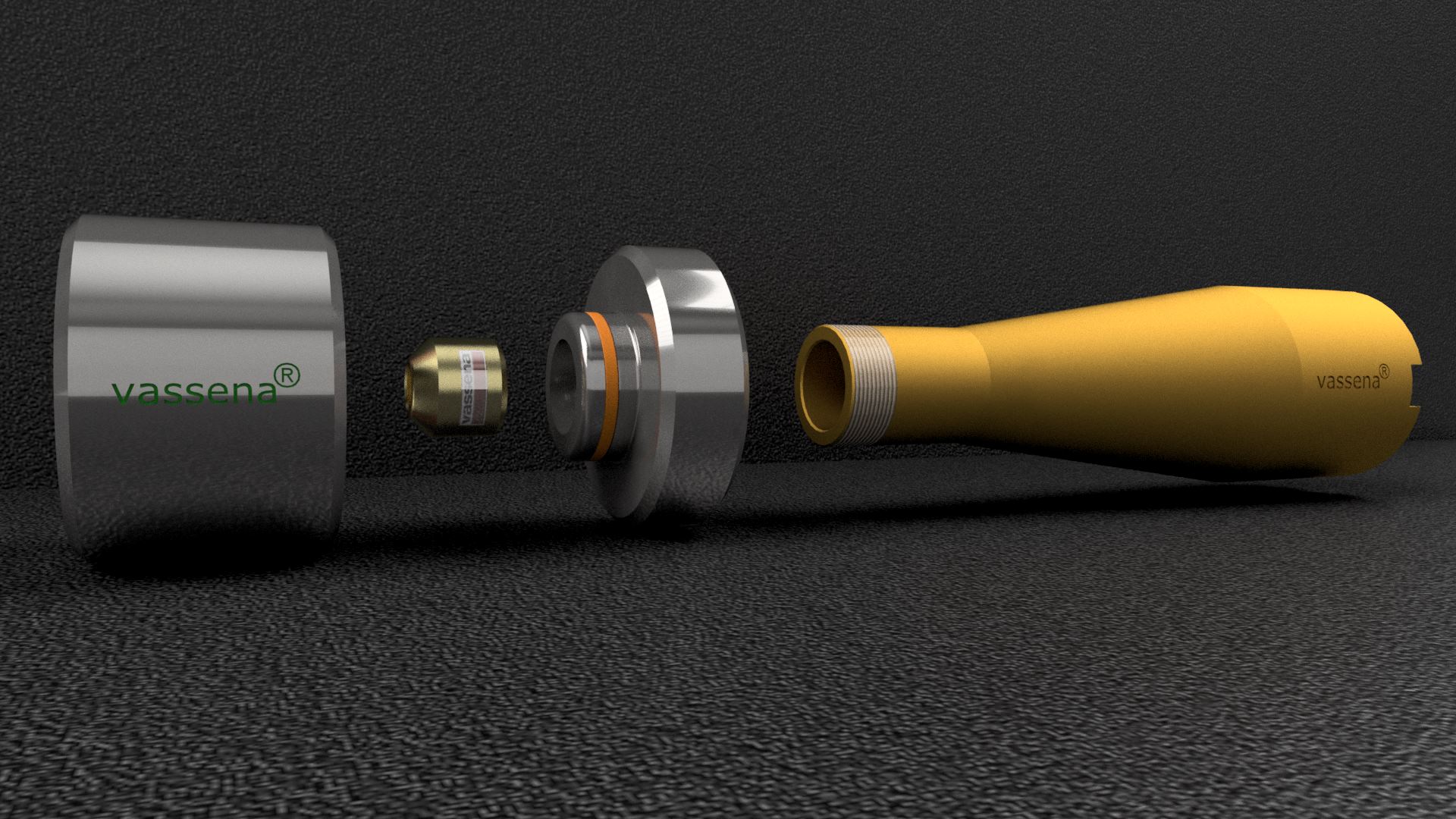

Vassena internationally patented VG402R.1 titanium

|

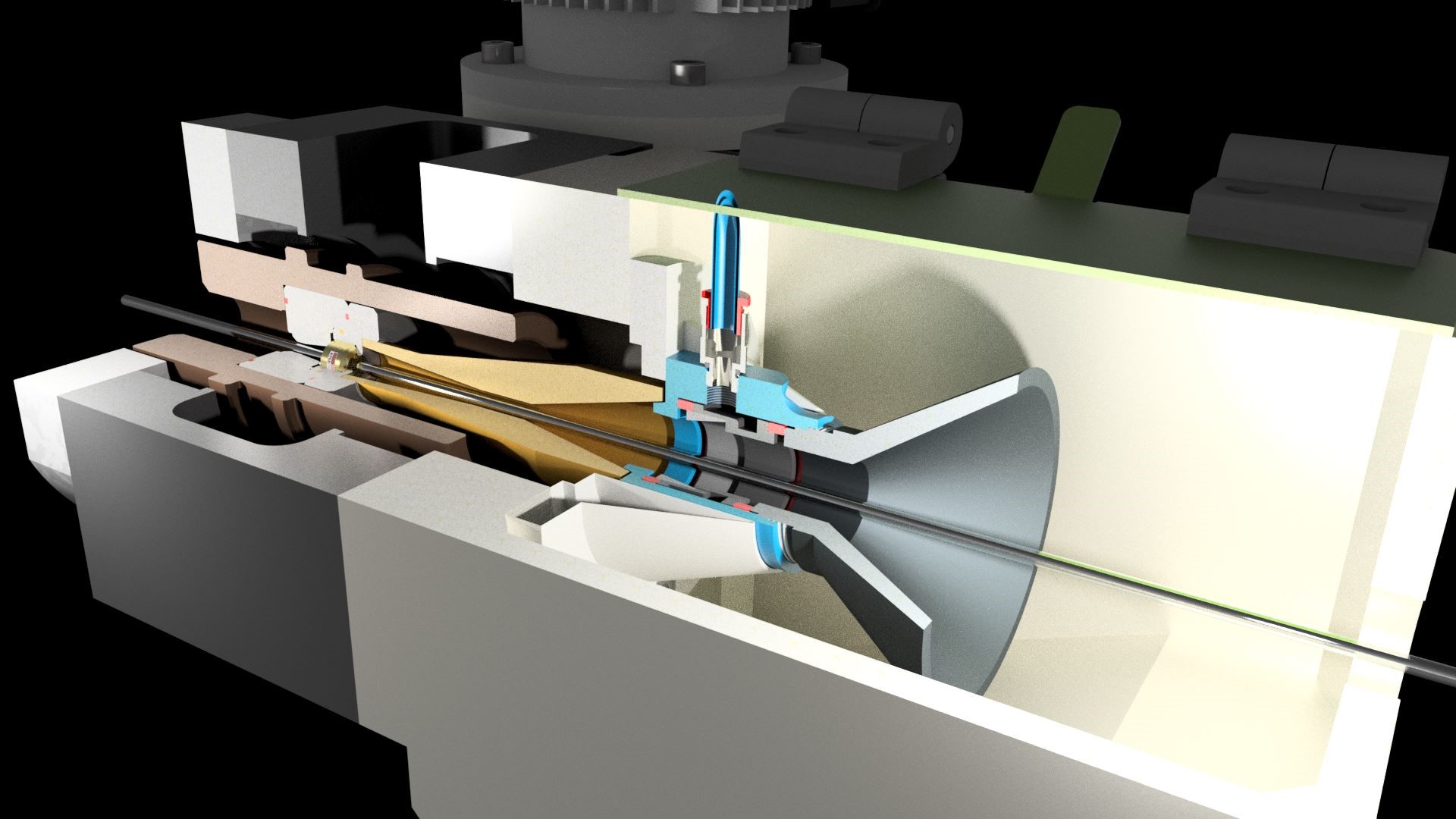

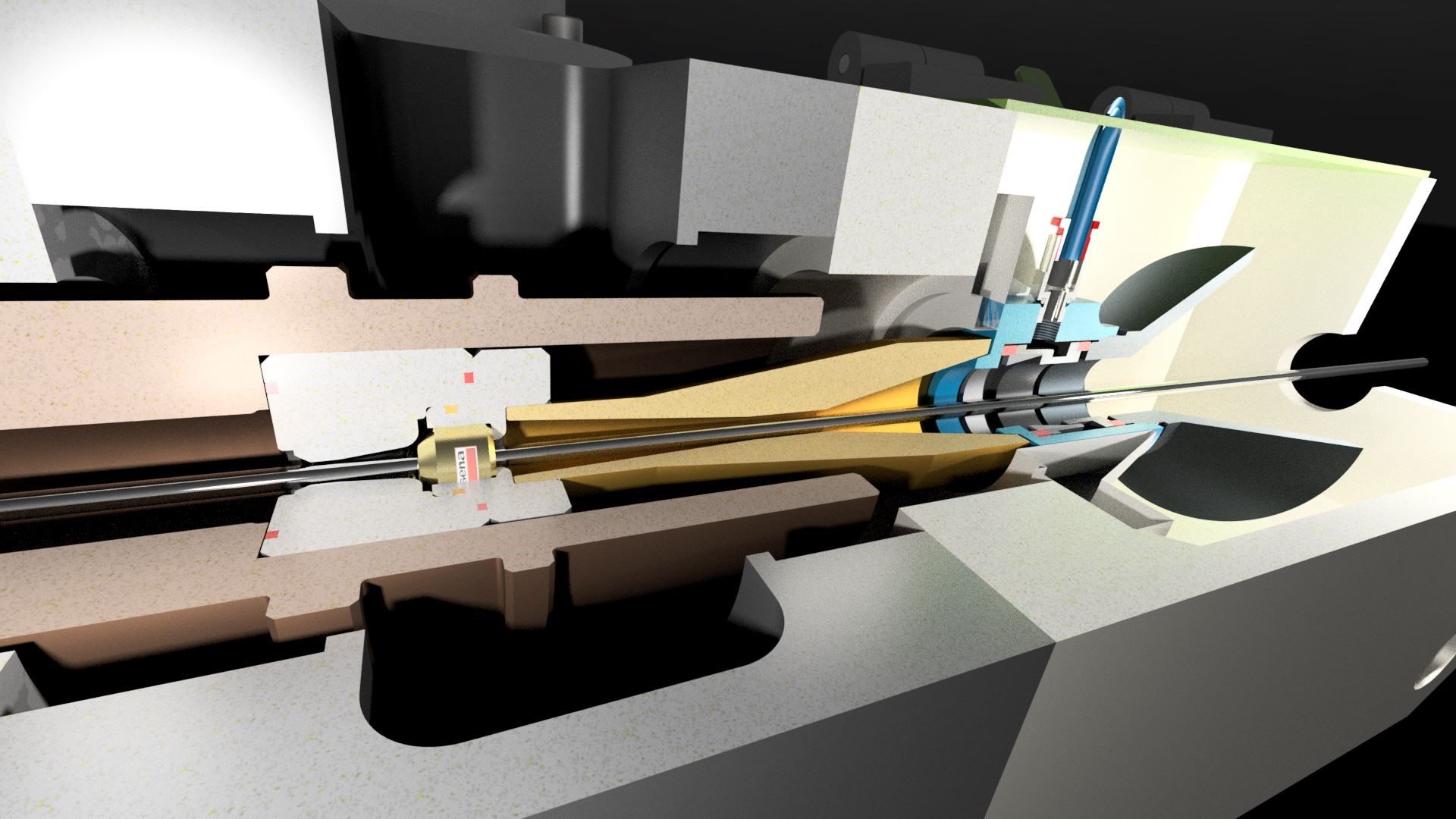

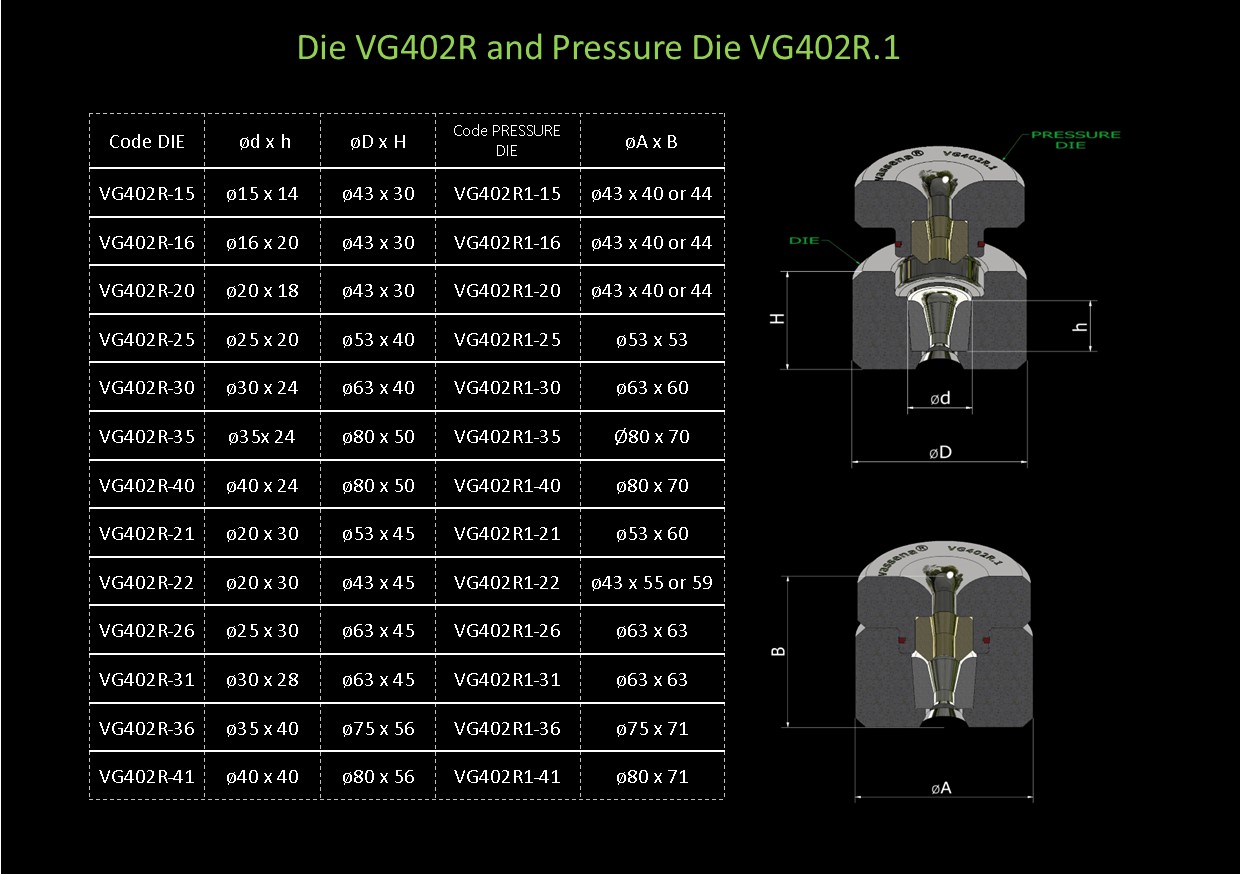

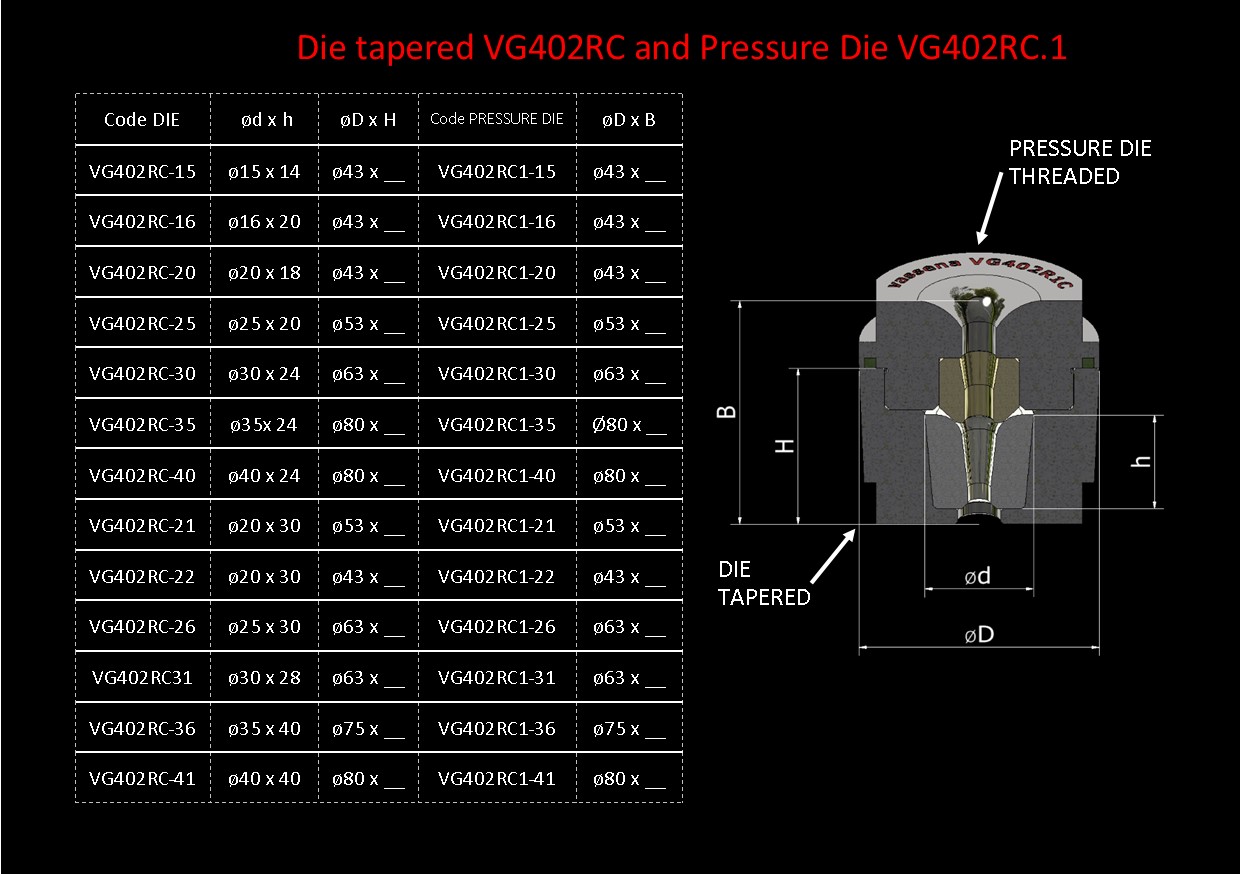

Vassena Dies unveils a world preview of the new drawing die VG402R.1, designed for high-speed wire drawing. It is equipped with an innovative pressure TITANIUM coated compass, developed according to a new criterion for the calculation of internal geometries, both of the chain and of the bush, in order to obtain a greater anchoring of the lubricant on the wire, thus reducing the friction generated during wire drawing. The result is an increased drawing speed and a significantly reduced cost incidence in the supply chain on the machining process. BENEFITS: 30% INCREASE IN DURATION in comparison to the old version VG402R The new pressure device VG402R.1 increases the lubrication of 200% compared to the old VG402R. BETTER QUALITY OF WIRE With dies Type "L", long nibs, there's a reduction of the drawing stress because of the lower friction, that allows a better plastic deformation LONGER LIFE OF PRESSURE DIES VG402R.1 With the titanium coating, the life of each pressure device is around three/four years. NO BREAKAGE OF DIES The nib is fixed into the steel case, to eliminate the vibration, causing the breakage of nibs. BETTER THERMAL DISPERSION Thanks to the appropriate size of the nibs compared to the holes RESPECT FOR ENVIRONMENT Vassena's dies can be repaired and re-used |

Chain and withdrawal sleeve VG402R "patented model"

|

|

A new pressure die improving wire lubrication by 200%

|

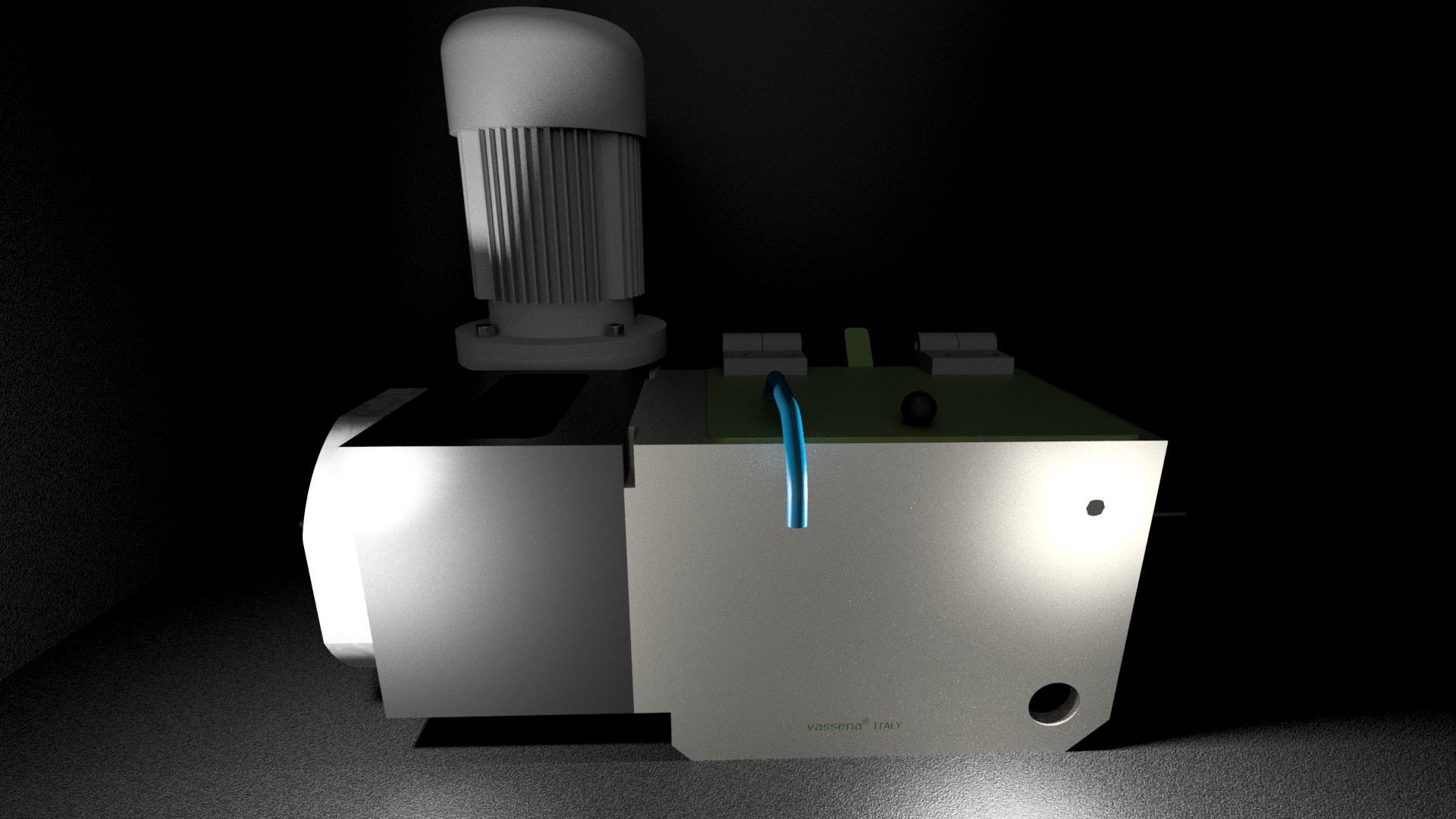

For more than 60 years, Vassena has been working closely with wire drawing companies and rope manufacturers in order to improve the profitability of their work and results. The eye has always been to the future, looking for innovative materials, geometries and cutting-edge technologies.

In line with this path, a brand-new patent arrives today: Vassena VG402R.2. It’s a new pressure die designed to allow a superior adhesion of the lubricant on the wire, up to 200% better than standard dies. The VG402R.2 has a special structure, which allows to reduce the friction coefficient ensuring higher drawing speed, better quality of the drawn wire and longer die life. Among the other advantages there are the elimination of the candle effect in the soap box and a healthier working environment - a benefit that involves the entire company, from the entrepreneur, to the manager, from the head of the workshop to the employees and workers. |