News

A new pressure die improving wire lubrication by 200%

|

For more than 60 years, Vassena has been working closely with wire drawing companies and rope manufacturers in order to improve the profitability of their work and results. The eye has always been to the future, looking for innovative materials, geometries and cutting-edge technologies.

|

Wire drawing evolves: drawing dies 4.0

In the last few months Vassena has been working on a brand new proprietary system: an application to generate a “dialogue” between drawing die and machine. From the very beginning, the early prototypes have shown promising results, and after the appropriate tests, the project is now a reality. The application sends signals with useful information to the software/operator for a 100% control of the finished product.

Among the collectible data are the wire temperature, the die deformation and any potential imperfection and unusual efforts, for a complete remote control of the production cycle. Vassena provides the sensors and the link to the software, developed in collaboration with one of the leading edge companies in this industry.

The solution is also compatible with all operating system. For more info, you can contact Vassena’s staff directly at: www.vassena.it

|

Vassena Filiere broadens out with diamond drawing dies

The historical company Vassena Filiere located in Malgrate (Italy) begins 2019 with a big novelty: diamond drawing dies are now part of the company’s production range.

After the introduction of pressure dies for diamond dies last month, Vassena is now able to provide the whole package: pressure dies plus diamond dies. Natural diamond dies, poly-crystalline synthetic diamond dies and mono-crystalline synthetic diamond dies, particularly suitable for the wire drawing of non-ferrous metals, can be supplied in a wide range of diameters, in order to meet all the needs of a wide customer base.

For more info, email info@vassena.it

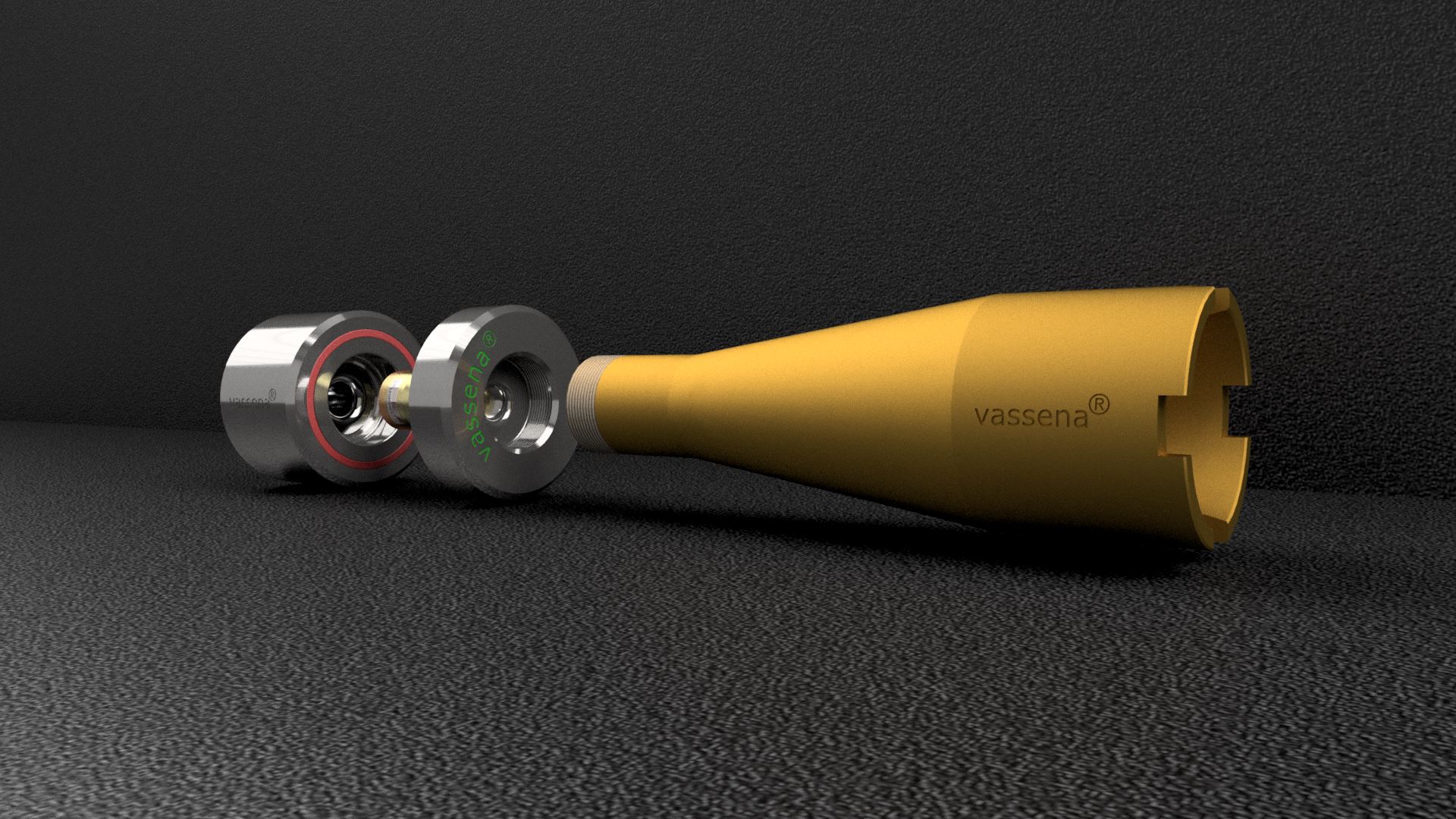

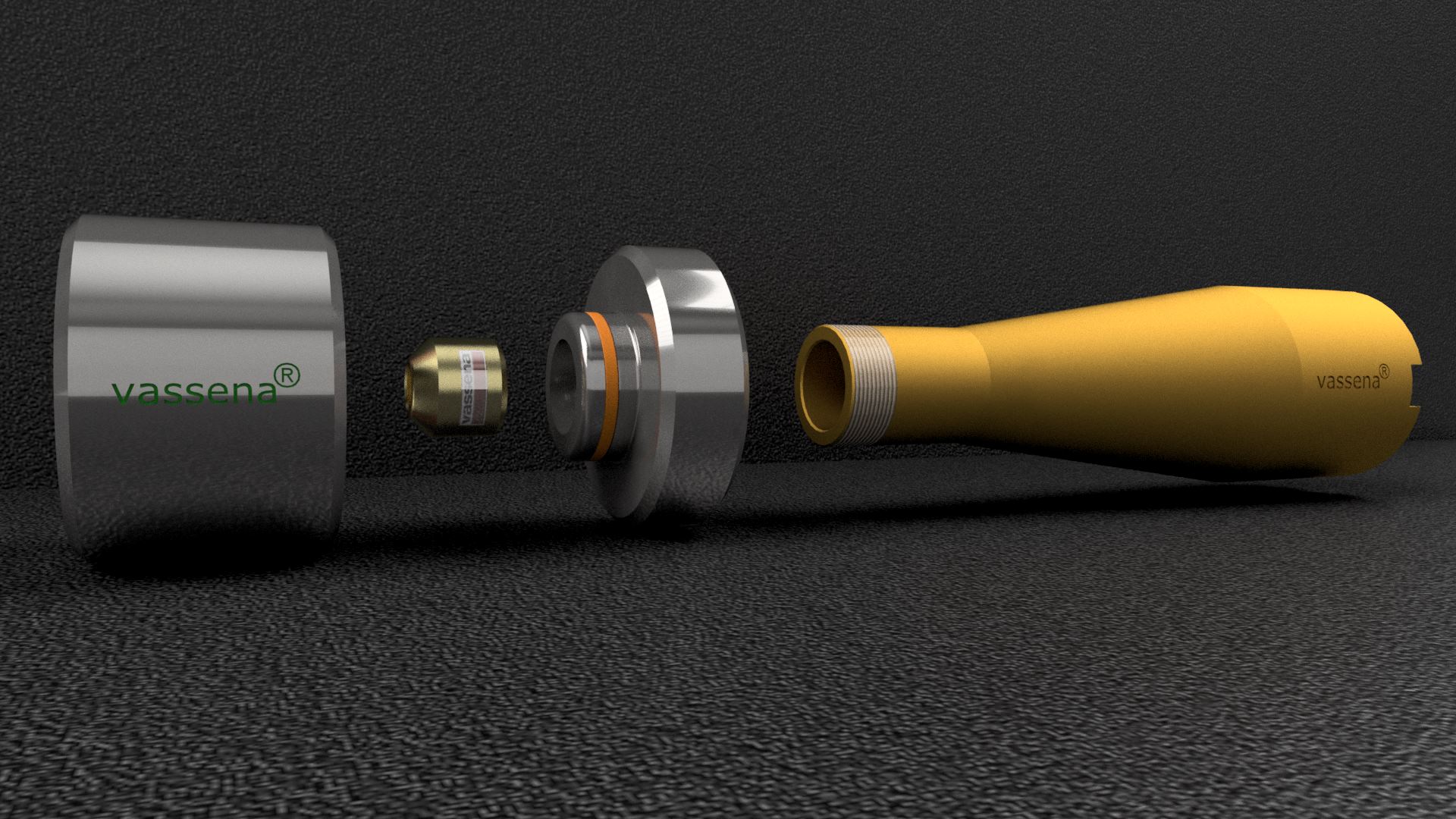

Pressure dies for diamond dies - new in Vassena's product range

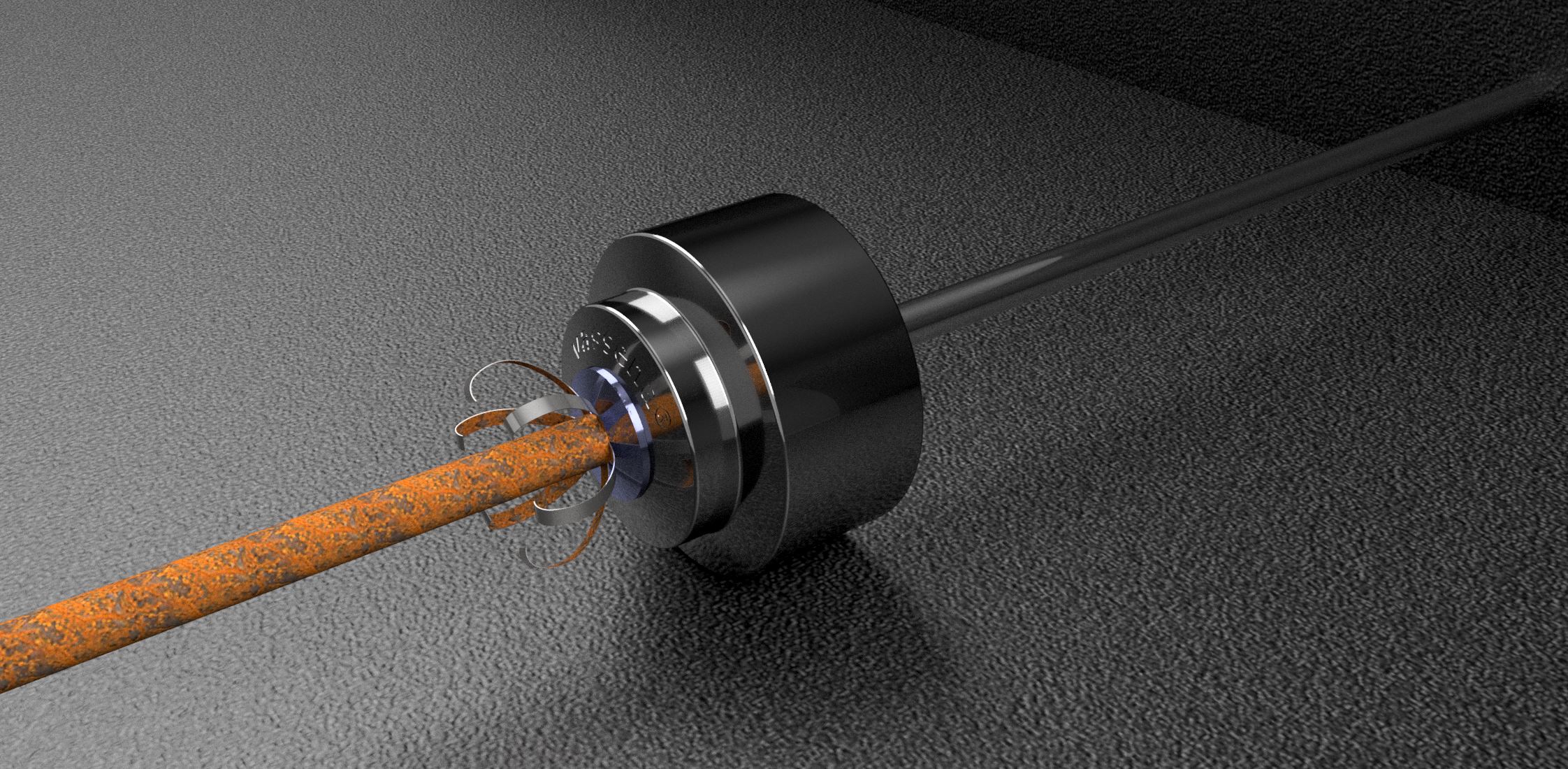

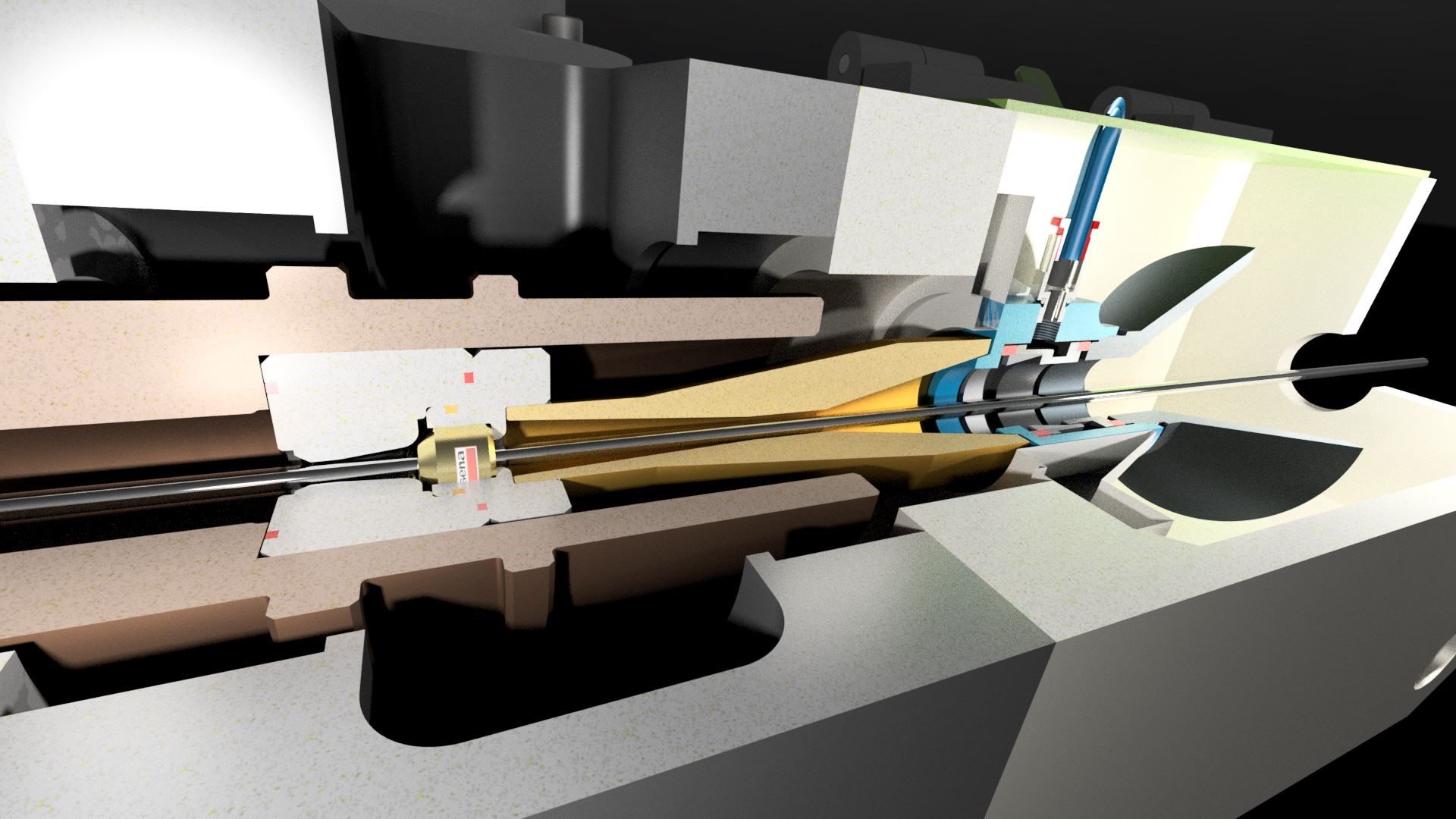

The pressure die system was developed by Vassena in order to reap the benefits of increased pressure and the consequently improved lubrication in both low and high-speed wire drawing processes.

Vassena taps into this innovative patented system applying it to polycrystalline diamond dies (PCD dies), especially designed for wire drawing of non-ferrous metals. The use of a pressure die prevents solidification of lubricant in the drawing die cone and allows an improved wire coating. The combination of these elements ensures reduced friction, less energy waste and most importantly a longer die life. Pressure dies and PCD dies can be easily and quickly assembled by operators without fuss.

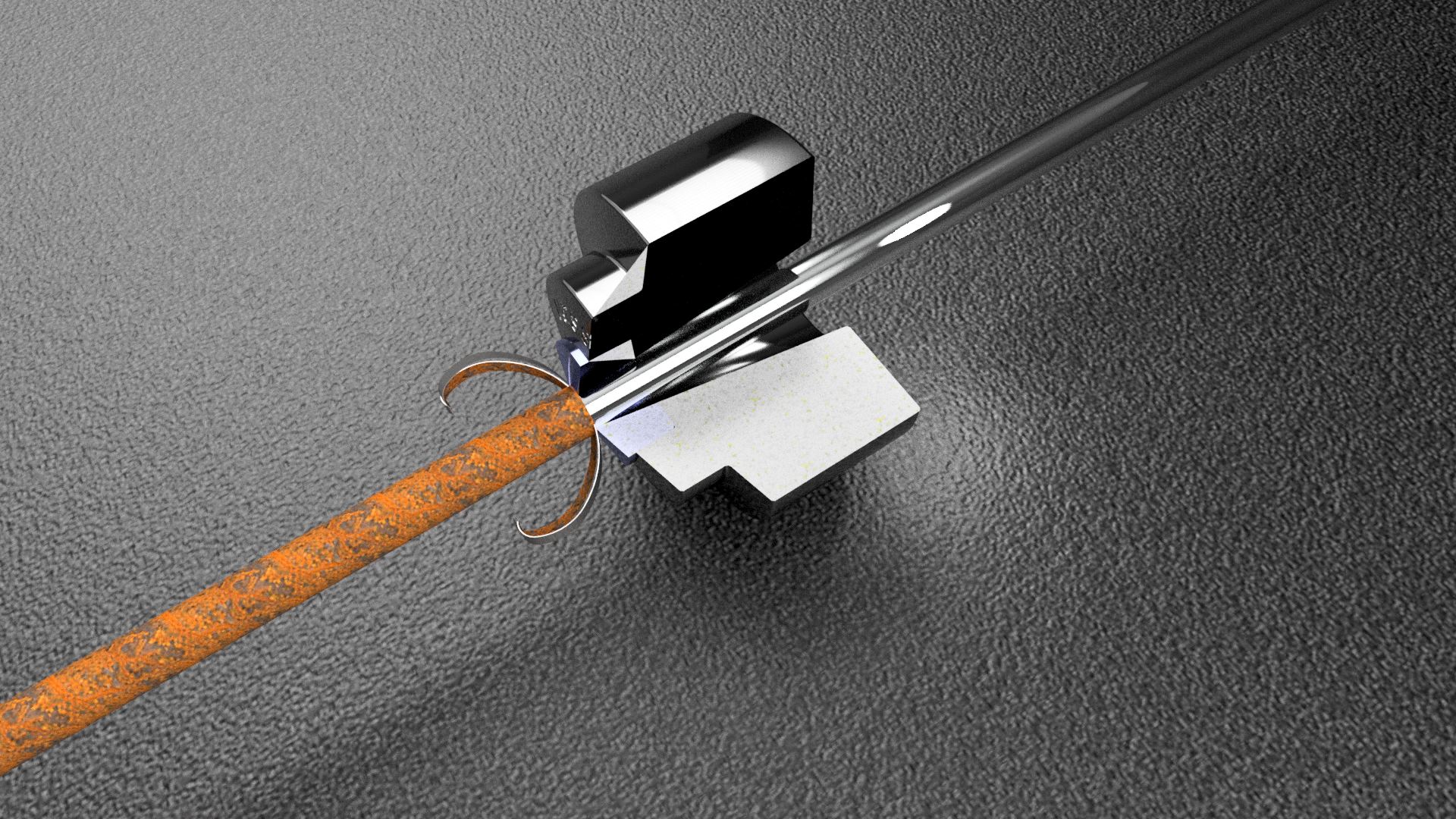

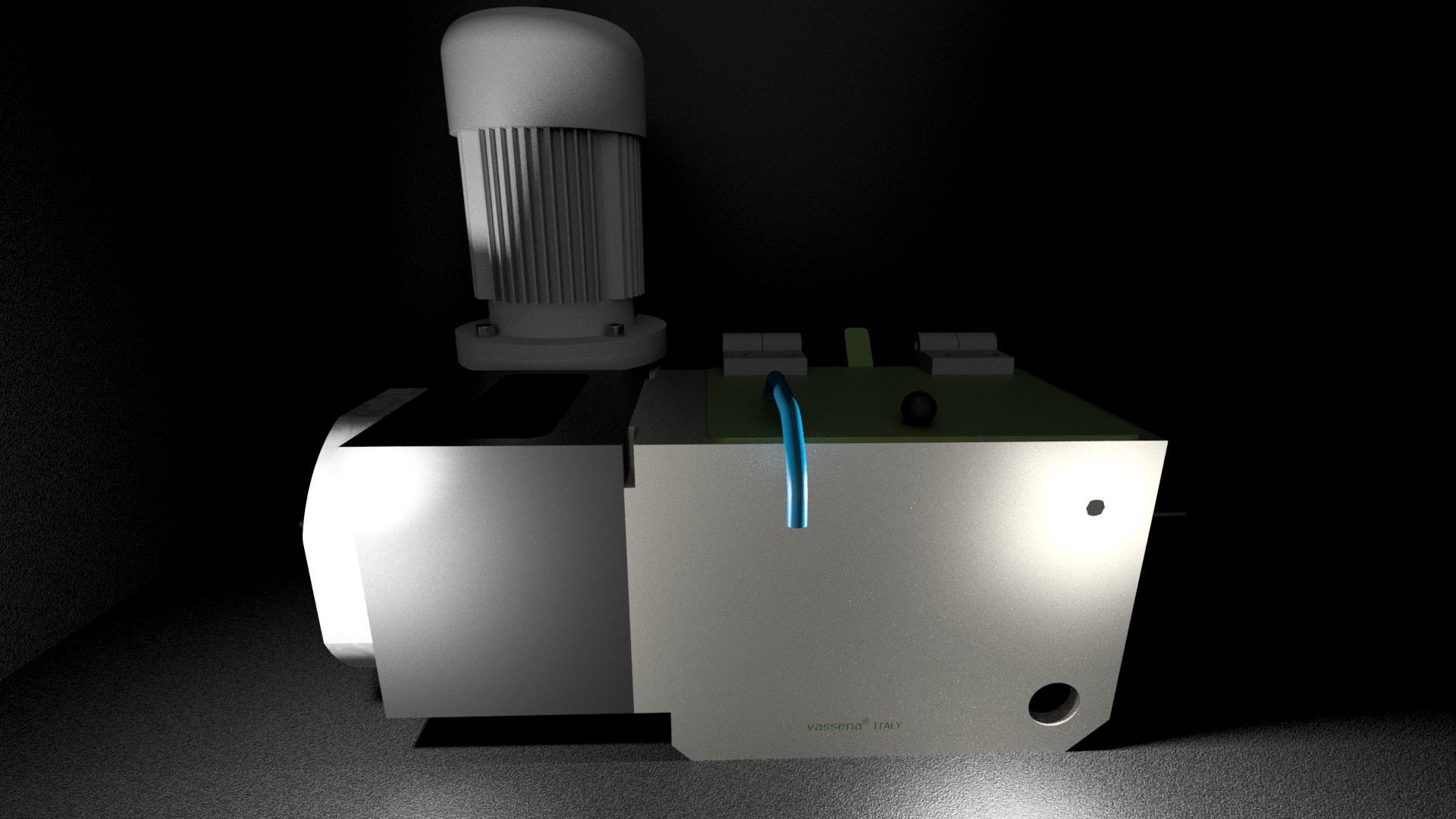

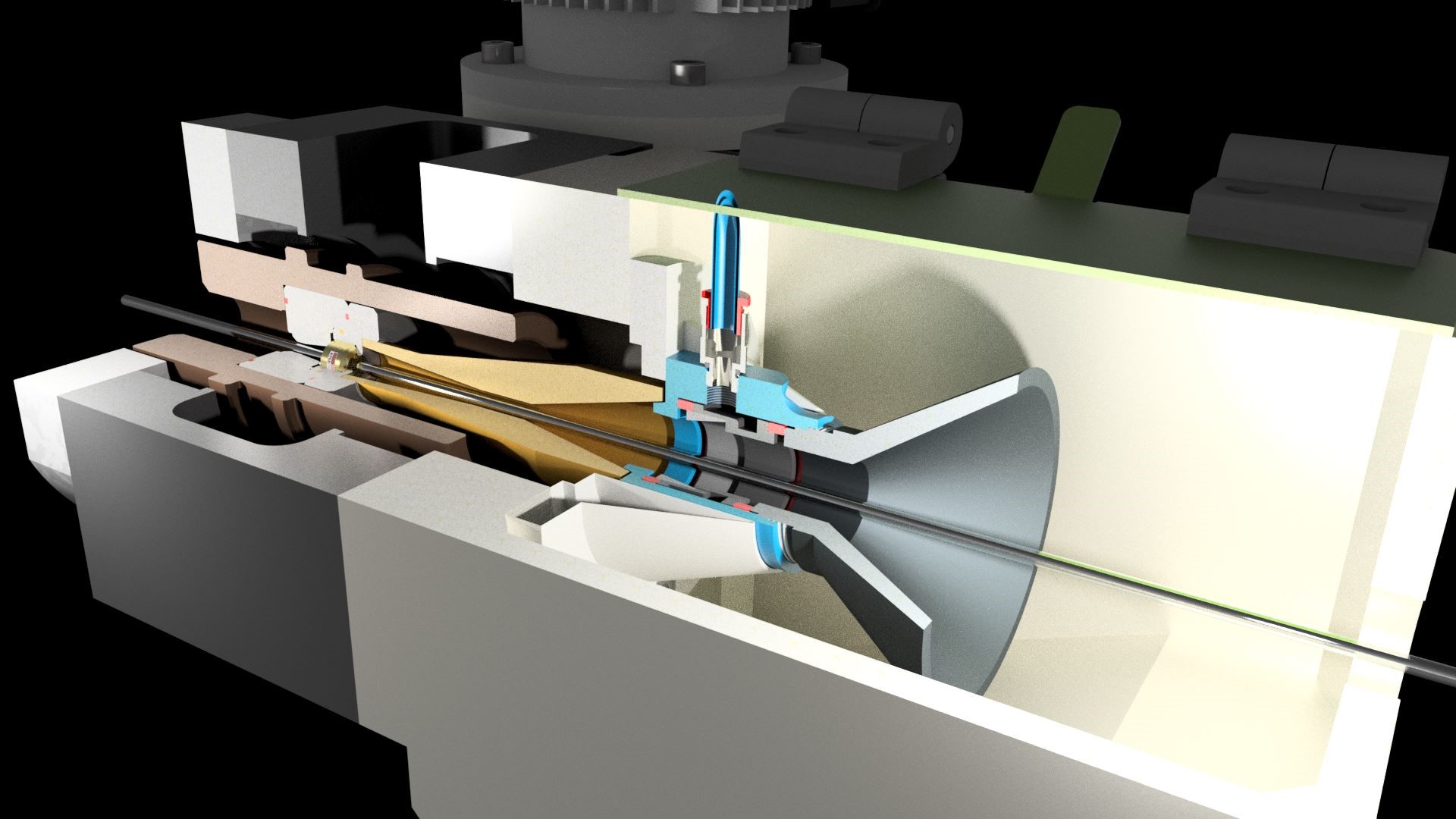

Vassena presents new internationally patented VG402R.1 Titanium coated die for high-speed wire drawing

Vassena Dies unveils a world preview of the new drawing die VG402R.1, designed for high-speed wire drawing. It is equipped with an innovative pressure TITANIUM coated compass, developed according to a new criterion for the calculation of internal geometries, both of the chain and of the bush, in order to obtain a greater anchoring of the lubricant on the wire, thus reducing the friction generated during wire drawing. The result is an increased drawing speed and a significantly reduced cost incidence in the supply chain on the machining process.

BENEFITS:

30% INCREASE IN DURATION in comparison to the old version VG402R

The new pressure device VG402R.1 increases the lubrication of 200% compared to the old VG402R.

BETTER QUALITY OF WIRE

With dies Type "L", long nibs, there's a reduction of the drawing stress because of the lower friction, that allows a better plastic deformation

LONGER LIFE OF PRESSURE DIES VG402R.1

With the titanium coating, the life of each pressure device is around three/four years.

NO BREAKAGE OF DIES

The nib is fixed into the steel case, to eliminate the vibration, causing the breakage of nibs.

BETTER THERMAL DISPERSION

Thanks to the appropriate size of the nibs compared to the holes

RESPECT FOR ENVIRONMENT

Vassena's dies can be repaired and re-used

Vassena at International Wire and Cable Trade Fair in Russia

We will be present at : FO/B42